Interactive Structures Lab

MEDICAL PROTOTYPES

Project Overview

As a part of CMU’s Interactive Structures Lab working with meta-materials, our focus was on the RUFFLES structure. Our task is to examine and experiment with the tensile properties of ribbon-like construction utilizing various materials. With the properties found we can develop working support bracing as well as flexible ankle prosthesis. My main focus was on the socket for the prosthesis and the carpal tunnel brace.

Role: UX Researcher, UI Designer, Prototyper

Type: Research academic work, material studies

Team members: Karina Shethia, Victoria Nguyen, Julia Anitescu, Karen Kang, alongside Prof. Alexandra Ion (faculty of HCI) at CMU.

Timeline: April 2022 - August 2022

💡Goal💡

Create an adjustable yet affordable carpal tunnel brace / lower ankle prosthesis that can be easily constructed by simple connector points and can be easily distributed world wide.

🔄 Process 🔄

LET’S GO 🦾

⚠️ Problem Statement

People of the disabled community or in need of bracing support cannot live their daily lives properly without the medical necessities required. Nowadays, prosthetic limbs and medical support braces can be very expensive, how can we give these group of people the best chance of obtaining the equipment needed?

👩💻 Market Research

Price

We first conducted some preliminary research on driving factors of the project — price. First looked into various brands and models of prosthetics. Price may vary however this is one of the factors we would like to change to give everyone equal opportunity for medical devices. Most below knee prosthetics have an average cost of $12,000 USD — we plan to cut this amount in half.

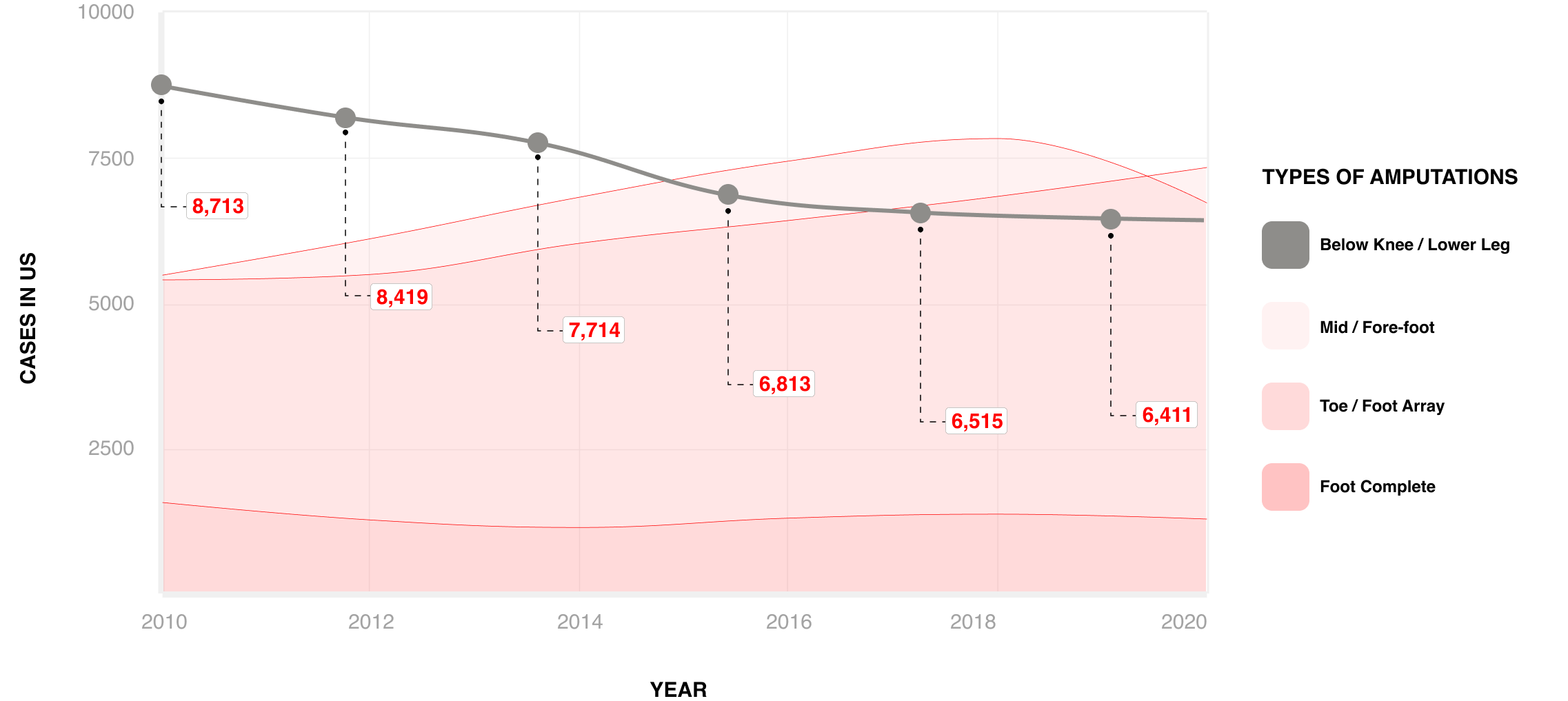

Number of Cases

We then started analyzing population wise — how many people in the US is actually needs this? Even though below knee amputation is decreasing annually due to new medical innovation, thousands of people are still in need of prosthetics that remain affordable yet customizable.

Carpal Tunnel Cases

Eventually after prosthetic research — we realized ruffles as a meta-material can be utilized for medical enhanced bracing. We honed in on the problem of carpal tunnel syndrome. Through some initial research we realized it is extremely prevalent especially today — COVID19’s work from home protocols drastically increases the chances of improper wrist posture.

In addition:

☑️ Anyone that sits at a desk!

☑️ WORKAHOLICS!

☑️ Prevalent to students

☑️ White collar workers

User Studies

🦾 Prosthetics Profile

Need to be able to remain physically active and a good range of motion.

Lightweight and flexible material to be able to easily move around.

Be able need to be customizable which allows simple and quick changes to be made on the prosthetic if needed.

🦾 Carpal Tunnel Profile

Need to be able to be secure on the wrist in a straight perfectly perpendicular angle to work station / laptop.

Feel comfortable and let user wear this device all day without any discomfort.

Be able need to be customizable to specific laptops and work stations — such as various angles and heights.

Wants & Needs Analysis

☑️ Easy Shipping ☑️ Cost Effectiveness ☑️ Careful Material Selection ☑️ Personalized Customization

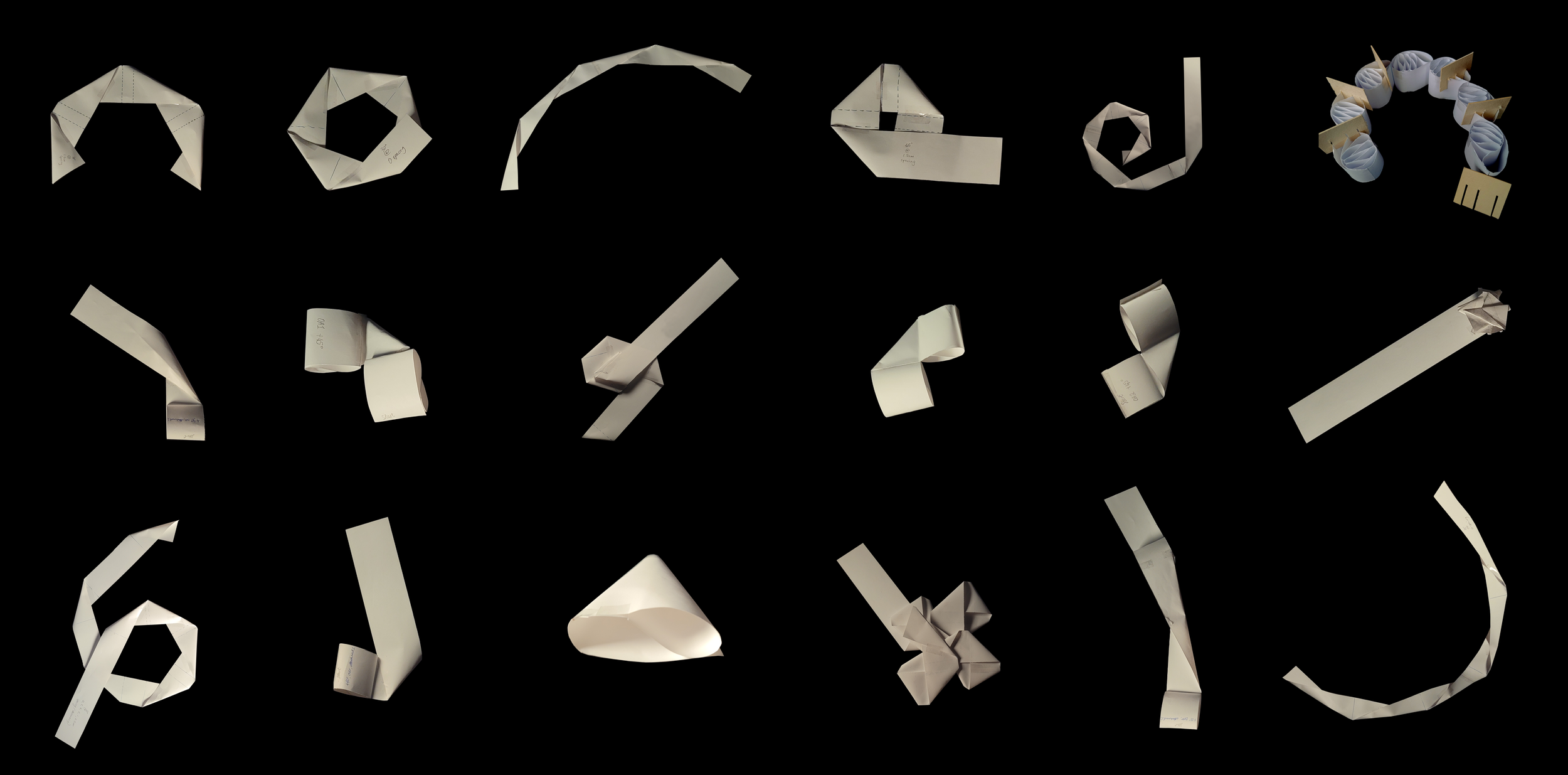

Paper

We first started with paper prototypes to mass produce and experiment with all possibilities of ruffles. This allowed us to understand the overall construction method, the tensile and compressive strength of the “Ruffles as a Meta-material”.

Cabinet of Curiosities

This rapid prototyping allowed us to experiment with what kind of shapes, directions, stiffness capabilities and methods of constructions Ruffles can implement. This allows us to rapid prototype actual designs for below knee prosthetics and carpal tunnel bracing.

Preliminary Paper Prototypes of Carpal Tunnel Brace

Plastic

As a team we eventually moved on to plastic prototypes for both below knee prosthesis and carpal tunnel brace. Since I primarily focused on the carpal tunnel brace — this was my first stab of utilizing a more secure, bendable and realistic material.

We created specific notches to allow for adjustability — this pushed us to think about attachments. In the carpal tunnel prototype tape was sufficient enough for the type of plastic used, however with the prosthesis smaller screws and nuts are required.

Final Prosthesis Prototype - Metal Sheet

This material allows for stability as well as flexibility for maximum mobility. One great thing about this material is it can be rolled into a tube that allows for easy transport anywhere. The notches are meticulously calculated for allowed adjustment and overall design of each ruffle is based on the forces of an actual foot. This allows for the most realistic and accurate design. However, further testing and evaluation needs to be attempted.

Socket Design

One of my greatest responsibilities were to design the socket for the prosthetic. The goals remain the same, design something affordable utilizing simple materials and construction methods, however allowing for customization and adjustability for users.

Final Carpal Tunnel Prototype

The final carpal tunnel prototype is made from black glossy vinyl — vinyl allows for flexibility as well as stiffness for security of wrist. Vinyl is also relatively easy to work with to puncture nodal points for screw attachment. With the notches, users can adjust angle of the brace by inserting or removing ruffles.

VIDEO TESTS:

User testing was an extremely long and tedious process. We needed to ensure the socket as well as the prosthesis can support the weight of humans of various sizes and heights. We also needed to ensure that the socket connected well with the prosthesis — it is important that it remained lightweight and comfortable for all users.

This is an ongoing project and process — further testing is still needed and further iteration on both prototypes of below knee prosthetics and carpal tunnel bracing. Further exploration of materiality and connection methods should also be implemented.

⏭ Next steps…

There needs to be tests and prototyping to be further explored — perhaps having real amputees and people suffering from carpal tunnel syndrome coming to test the product. Since this is an on-going project, further new materials and new ways of attachment needs to be tested with the notches. Additionally a model needs to be implemented with current market products to see how this one can compare, once we have the proper numbers and logistics we can start implementing a business model to see how this can be shipped throughout the world — which is really the ultimate goal.

📚 Take Aways

This entire project and process taught me the importance of working with members of other fields. Even though I was on the design and prototyping team, we had to work with many external members on the biomedical and engineering team — to understand force distribution and how a foot / wrist actually functions. This project also taught me the importance of rapid prototyping; test, experiment and just playing with the material can help us identify new construction methods and ways of creating.